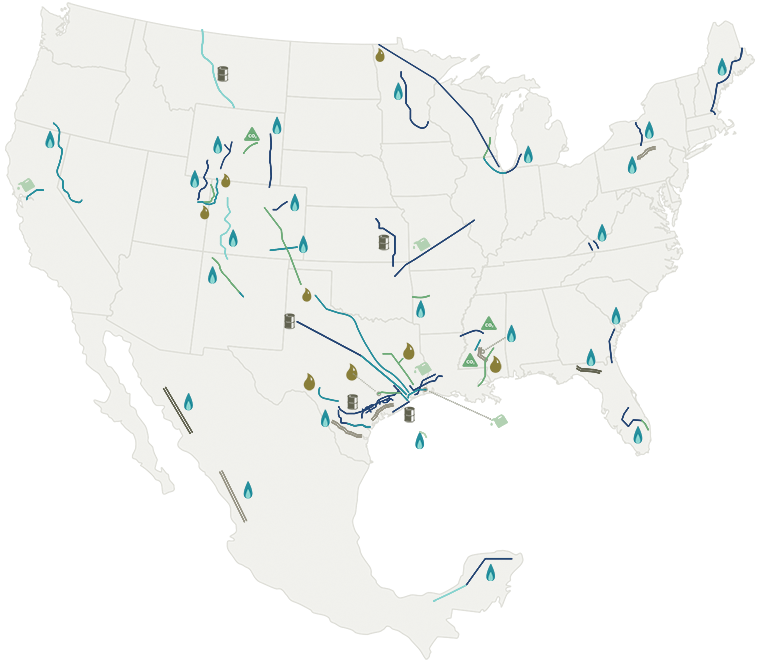

Experience

For more than six decades, Stupp has been helping make America’s quest for energy independence a reality. With projects spanning the globe from Albuquerque to Australia, there’s no application that our skilled production team and logistics professionals can’t handle.

Map Key×

Click the options below to interact with the map.

Click the options below to interact with the map.

HFW

- 16"

- 18"

- 20"

- 22"

- 24"

SAWH

- 30"

- 36"

Fluid

Oil

Oil Natural Gas

Natural Gas Liquids

Liquids CO2

CO2 Products

Products

The graphic above represents some of the major projects that Stupp has supplied over the years. While we couldn’t illustrate our entire history on the map, we’ve made enough pipe over the past five years alone to stretch from Portland, Oregon, to Portland, Maine and back!